A 2-in-1 soldering and hot air rework station is a versatile tool that streamlines your electronics repair work. However, even high-quality units can experience issues over time due to frequent use, poor maintenance, or incorrect operation.

This guide covers the most common problems with 2-in-1 rework stations, along with practical solutions to keep your equipment in top condition.

1. Soldering Iron Not Heating Up

Cause:

- Burned-out heating element

- Loose or broken wiring inside the handle

- Faulty temperature control circuit

Solution:

- Check the iron’s power cable and connector

- Test the heating element for continuity and replace if faulty

- If wiring is intact, the control board may need repair or replacement

Tip: Always use original Gordak spare parts for reliable performance.

2. Hot Air Gun Has Weak or No Airflow

Cause:

- Clogged nozzle or air intake

- Faulty air pump or turbine

- Damaged air hose

Solution:

- Clean the nozzle and air filter with a soft brush or compressed air

- Ensure the air hose is not pinched or blocked

- If the pump is noisy or non-functional, it may need to be replaced

3. Inaccurate Temperature Display

Cause:

- Sensor drift due to prolonged use

- Faulty thermocouple or control board

- Calibration error

Solution:

- Use a thermometer to verify actual temperature

- Replace the thermocouple if it’s providing false readings

- Recalibrate your station if supported by your model

4. Intermittent Heating or Power Cutouts

Cause:

- Loose internal wiring or poor solder joints

- Power supply instability

- Overheating protection kicking in

Solution:

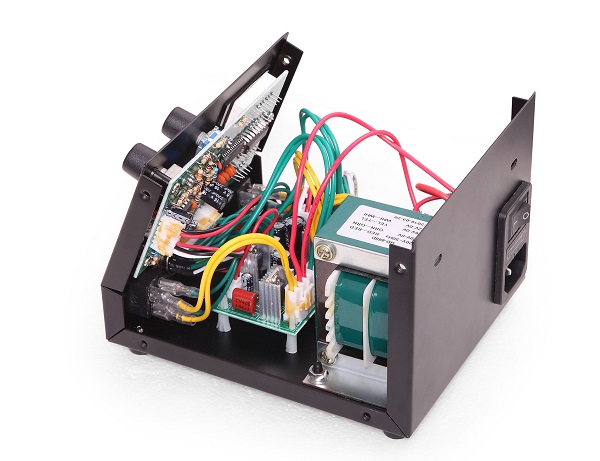

- Inspect internal connections if you’re trained to open the unit safely

- Avoid sharing the power outlet with high-drain devices

- Ensure proper ventilation around the station to avoid overheating

5. Hot Air Gun Overheats Quickly

Cause:

- Excessive temperature settings

- Blocked airflow causing heat buildup

- Defective thermostat or sensor

Solution:

- Operate within recommended temperature ranges (typically 200–450°C)

- Keep the airflow unblocked and check the fan/pump

- Replace the sensor if it fails to regulate heat properly

6. No Display or Station Won’t Power On

Cause:

- Blown fuse or faulty power supply

- Faulty power switch

- Burned circuit board components

Solution:

- Check and replace the fuse if necessary

- Inspect the power cord and switch

- If no visible damage, consult a technician or the manufacturer

7. Rapid Tip Wear or Oxidation

Cause:

- Excessive temperature use

- Lack of tip cleaning and tinning

- Poor-quality solder

Solution:

- Use appropriate soldering temperatures (300–350°C for most jobs)

- Clean the tip with brass wool and tin it after each use

- Use high-quality, lead-free solder with flux

Final Advice: Preventive Maintenance Is Key

Many issues with 2-in-1 rework stations can be prevented with routine care. Refer to our Maintenance Guide for best practices.

Why Gordak?

At Gordak, we manufacture durable and affordable 2-in-1 rework stations, offering factory-direct pricing for dealers and workshops. Our products are designed for precision, safety, and longevity — supported by our responsive technical service.

For inquiries or bulk orders, email info@gordakelec.com.