With lots of improvements in technology, the soldering station has profited greatly and this has resulted in different designs of soldering devices. Apart from the existing stations, some emerging stations focus on a special job request.

Beyond just being a simple soldering station, these new sets of machines deliver an improved operation and enhanced performance. Apart from the use of soldering stations for mere soldering tasks, they can also be used to operate on the different integrated circuits.

The efficiency or performance of a soldering station is a function of its make and that is why it is important to partner with a reliable and trusted soldering station manufacturer to get the best brand.

Some essential factors should be looked into before you buy a soldering station and this includes the following:

1. Heat Up Time

If you consistently have a soldering task to deal with, then the tip of the soldering iron should heat up in a short time for you to meet up.

A station that has high heat-retaining ability will give improved thermal efficiency and a shorter heat-up time.

2. Temperature and Wattage Control

For most of the soldering tasks in the electronic industries, a soldering station with around a 40-watt power rating is sufficient.

However, a soldering station with a higher rating capacity can serve as a reserve and can come in handy in some certain cases.

An adjustable soldering station is a more effective choice that allows the regulation of temperature and wattage and most of the soldering stations have an adjustable knob to achieve this.

3. Electrostatic discharge Safety

One major cause of failure in a soldering station is sudden electrostatic discharge and so it advisable to go for a product that is protected against it.

With this in place, it will go a long way to improving the quality of work and durability of the station.

4. Soldering Tip Cost

One thing that you need to constantly change in the use of a soldering station is a soldering tip as it undergoes tear and wears with use.

A very good choice of the station to acquire should be one that allows the use of cost-friendly soldering tips during replacements.

We have some varieties of stations available and these are:

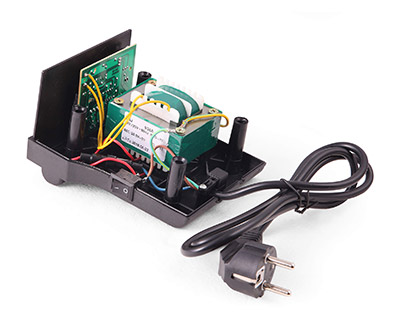

1. Contact Soldering Station

This type of soldering station is the most common and gained a lot of acceptance amongst users.

The thermal level and the voltage of this station can be regulated by an in-built power source to a particular value based on its application at the point in time.

2. Infrared Soldering Station

For an advanced form of soldering, you will need the infrared soldering station which focuses a beam of radiation on the target object for soldering thereby preventing any mechanical impairment or excessive heating.

3. Hot Air Rework Station

The name “hot air” soldering station, implies that the components can be preheated and thus makes it useful for operating on surface mount technology components.

Other areas of use are DIP (Dual Inline Packaging), SOIC (Small Outline Integrated Circuits), and other IC units.

4. Lead-Free Soldering Station

These are products known for their relatively cheap cost but are limited to use in a market that prohibits the use of leaded materials.

They make use of a zero-lead solder and offers an improved efficiency to soldering activities.

They usually need additional heat to melt the solder and so it is advisable for the supplier to give the soldering station manufacturer vital information on how to cut down costs with regards to this.

In need of a top-quality soldering station?

The tips needed to choose the best soldering station for a given job have been shared in this article but you need to partner with a reliable and trusted soldering station manufacture for your products.

At Guangdong Shunde Gordak electronic company, we manufacture top quality and standard soldering stations that are reliable and durable. Our team of high-tech professionals is committed to giving you the best and our delivery system is top-notch. Kindly check to see our lists of products and make your order now.

Soldering Stations: Usage, Selection & Maintenance

What Defines a Good Soldering Iron?

A Complete Buyer’s Guide to Soldering Stations

How to Properly Use a Soldering Station

Choosing the Right Soldering Station for Your Needs

How to Choose a Quality Soldering and Rework Station

Tips for Choosing the Right Choice of Soldering Station

How To Use A Soldering Station

The Best Soldering Iron of 2024: A Comprehensive Guide

Maintaining Your Soldering Iron: Best Practices